Choose the way you work

Quickly switch between manual mode and robot-managed automatic setting. Automated press brakes are easy to use.

Perfect integration with the press brake

Grazie ad una unità intelligente che gestisce robot e piegatrice.

Maximum precision

Thanks to the sensors and the perfect coordination

Easy to use

Intuitive management thanks to the touch-screen and joystick. Switch easily from automated press brake to manual press brake.

Everything is possible with .Matrix automated press brake

The MATRIX robotic bending cells are machines which are today in great demand on the market, designed to take up, fold and deposit profiles in metal sheeting.

All completely automatically.

Using robotic press brakes is to guarantee the quality of the finished product, substantial reduction in costs, and the safeguarding of health.

- It relieves operators from repetitive, strenuous and risky tasks

- It reduces costs because it reduces the discretion of the human factor

- Increase production cycle times

- Speed up the work of people involved in other areas

VICLA has studied various solutions to make the bending phase increasingly efficient.

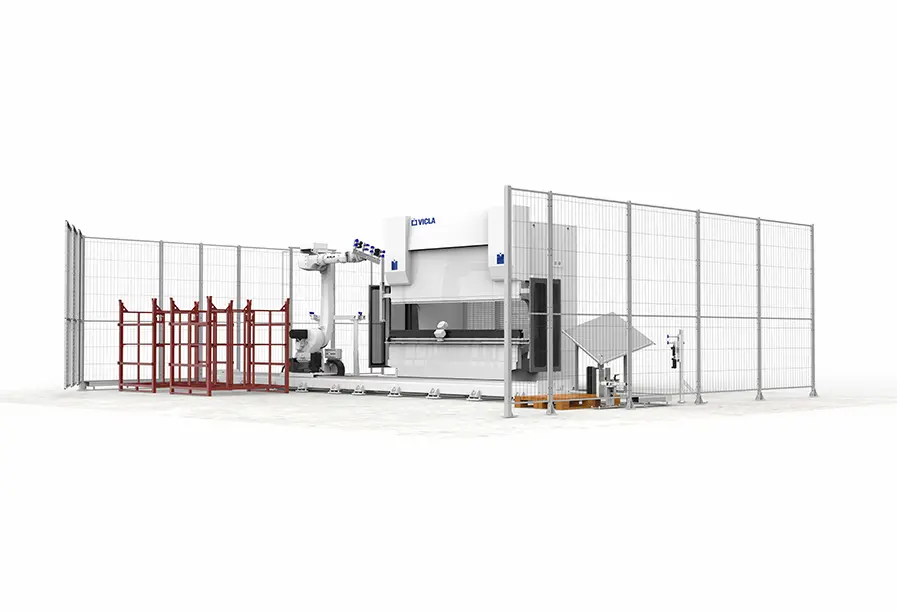

.VICLA MATRIX BASELINE

Robotic bending cell with hybrid press brake and ground-based rail robot.

CONTACT US

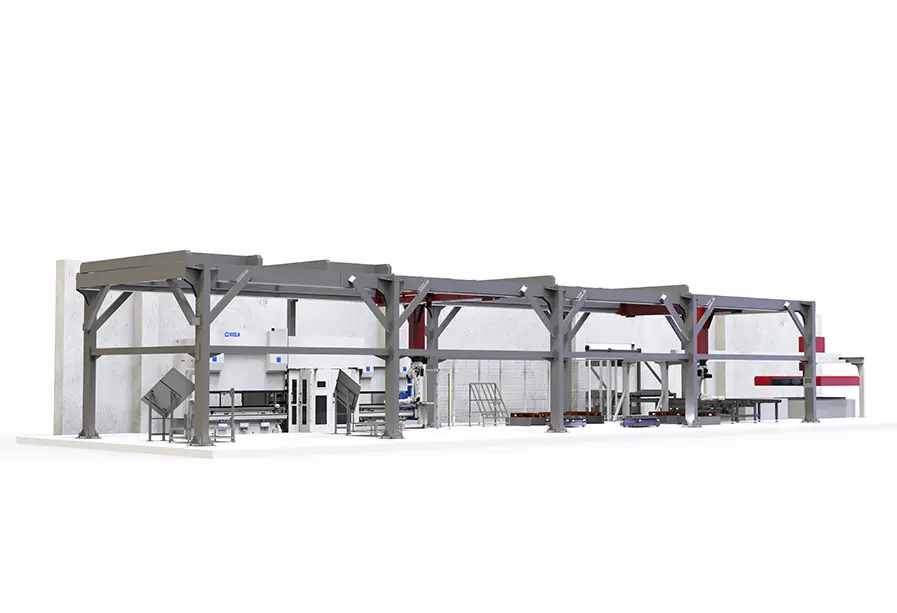

.VICLA MATRIX SKYLINE

Robotic bending cell with hybrid press brake and portal robot.

CONTACT US

.VICLA MATRIX TAILOR

Tailored-made solutions such as automatic production line from laser to bending

We can configure the system so that the laser cutting phase and the subsequent bending phase are managed by a single robot. Combined with laser cutting, the robot is capable of:

- Manage the sorting by dividing the pieces cut by the laser

- Prepare correct palletization for bending

- Run the folding cycle

CONTACT US

CONTACT US.

Our experts will provide you with all the information you need about our products and services.

Fill out the form.

A DIRECT CONTACT

The first step is at our place.

TRUST IN THE FIRST PLACE

Before and after the sale.

ANYTIME YOU NEED IT

to solve any kind of problems.