The art of press brake bending is often underestimated. Companies, sometimes unconsciously, prioritize other areas of their production chain. For example, they may invest in state-of-the-art technical offices while using outdated press brakes.

Sheet metal is a challenging material to bend, and underestimating its complexities can lead to costly mistakes. Fortunately, technological advancements have enabled manufacturers to develop efficient press brake equipment.

While press brakes have matured in terms of operation and structure, the equipment used to enhance and increase their performance has also evolved.

Essential Equipment for Press Brakes:

-

Hybrid systems: modern hybrid systems offer exceptional energy savings and precise beam positioning (accurate to thousandths of a millimeter). VICLA, for example, has created the .Superior press brake, which allows to save up to 78% of energy consumption compared to hydraulic press brakes.

-

Active crowning: Automatic systems with sensors ensure consistent bending angles throughout the workpiece.

-

Multi-axis backgauges: Quick and accurate positioning of backgauges is crucial for complex shapes and small batches.

-

Off-line programming (CAM): Standardize processes and transfer expertise to new operators.

-

User-friendly numerical control: Intuitive interfaces facilitate easy operation for both experienced and inexperienced operators.

Press brakes with hybrid technology

For most processing, a hybrid system of the latest generation guarantees an indisputable energy saving and can position the top beam with an accuracy in the order of thousandths of a millimetre.

These are all benefits that bring great economic savings for the company.

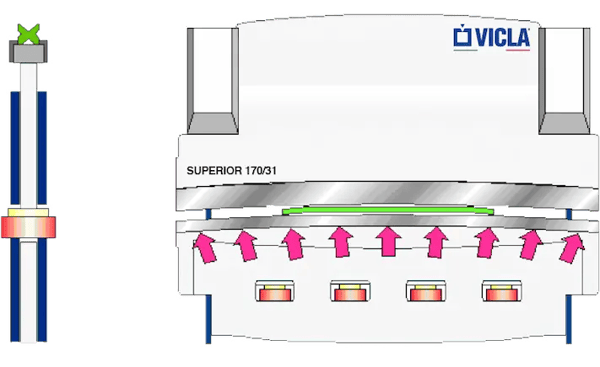

Real time crowning

As is known, press brakes are subject to natural structural deformation during processing.

As is known, press brakes are subject to natural structural deformation during processing.

Bending of the top beam is the most obvious.

An automatic system with special sensors located in strategic areas of the press to ensure that the punches and dies are the right distance apart along the whole length of the working area is undoubtedly an invaluable benefit.

This ensures that a bent workpiece will have the same desired angle in the middle as at the ends.

A multi-axis backgauge for press brakes

Having backgauges that can be positioned quickly and accurately almost anywhere has become a must.

In fact, the market increasingly demands production of high-quality complex workpieces in small batches: tapered bends, edges that are not parallel to the deformation line, processing stations and so on. With multi-axis backgauges, these and many other complex processes can be carried out more easily.

Metal bending off-line programming

On other words: standardisation.

Being strictly linked to the human factor, bending efficiency depends on the skill and experience of the operator, as well as the quality of the machine used.

Where the company has a high personnel turn-over or a growth in volumes that must also be supported by an increase in personnel, the use of CAM can be extremely useful in bending.

In fact, in this case the know-how and experience of an expert can be “spread” over the new recruits in a short time, bringing great benefits to production.

CNC press brakes have user-friendly numerical control

In any case, even if there is no off-line programming, numerical control is the main tool that allows even unskilled press brake operators to interface effectively with their machines in a short time through a clear, simple and complete interface.

When the start-up time of a new machine is longer than expected, the problem is often due to difficulty in understanding and controlling an unclear system, which can create problems for operators, regardless of whether they are expert or inexperienced.